SEMI-F63超纯水使用指南

SEMI F63-0701

GUIDELINES FOR ULTRAPURE WATER USED IN SEMICONDUCTOR

PROCESSING

This specification was technically approved by the Global Facilities Committee and is the direct

responsibility of the North American Facilities Committee. Current edition approved by the North American

Facilities Committee on April 30, 2001. Initially available at www.semi.org May 2001; to be published July

2001.

1 Purpose

1.1 This guide is provided for mul tiple purposes. It

may be used as a basis for establishing performance

criteria for purchases of new UPW equipment. It may

also be used internally by facility engineers to set

process control parameters for the operation of their

UPW systems. This guide may be used by process

engineers to establish reasonable expectations about the

quality of the UPW being supplied to them by facilities.

NOTICE: These suggested guidelines are published as

technical information and are intended for

informational purposes only.

2 Scope

2.1 Water is used extensively in th e production of

semiconductor devices for all wet processing steps such

as the rinsing of wafers. Ultrapure Water (UPW) is

typically produced for this purpose using Reverse

Osmosis/Deionized resin bed technologies. The quality

of the water impacts device yield and as linewidths

decrease, requirements for higher purity water may

increase.

2.2 This standard does not purport to address safety

issues, if any, associated with its use. It is the

responsibility of the users of this standard to establish

appropriate safety health practices and determine the

applicability or regulatory limitations prior to use.

3 Referenced Standards

NOTE 1: As listed or revised, all documents cited shall be the

latest publications of adopted standards.

3.1 SEMI Standards

SEMI F61 — Guide For Ultrapure Water System Used

in Semiconductor Processing

3.2 ASTM Standards1

ASTM D-5127 — Standard Guide for Ultra Pure Water

Used in the Electronics and Semiconductor Industry.

ASTM F-1094 — Test Method For Microbiological

Monitoring of Water Used For Processing Electron and

Microelectronic Devices by Direct- Pressure Tap

Sampling Valve and by the Pre-sterilized Plastic Bag

Method.

4 Limitations

4.1 This guide is not intended to s et an absolute

number for performance of a particular UPW system.

Performance guidelines should be determined based on

the design of the UPW system, the components used in

the water system, the sensitivity of the manufacturing

process to the purity of the water, the sensitivity of the

instrumentation, and the budget available to maintain

and monitor the water system.

4.2 This set of guidelines has been established from a

variety of sources and inputs including 1.) an industry

survey that SEMI provided to members of its standards

activities in facilities; 2.) typical UPW levels from a

large selection of semiconductor UPW systems as

measured by several independent laboratories that test

high purity water for the semiconductor industry; 3.)

specifications from water system equipment

manufacturers; 4.) and input from producers and users

of UPW during SEMI standards committee meetings

and through the balloting process. However, it is up to

each individual owner of a UPW system to set

specifications for the purity of its water based on its

own needs and available resources.

4.3 This guide is reflective of a particular design

approach for a UPW system. The guidelines can be

produced from a properly maintained UPW system as

described and diagrammed in SEMI F61 and is typical

output from existing high-end semiconductor

manufacturing plants with state-of-the-art water

systems. The purity of water generated in other types of

water systems may differ greatly.

4.4 The guidelines are targeted to UPW produced for

semiconductor manufacturing. There exists an ASTM

standard D5127 which should be considered in setting

specifications for the purity of reagent grade water

needed in a laboratory for analytical testing of

semiconductor materials and process chemicals.

5 Use of the Guidelines

5.1 Sampling methods and contamination control are

of paramount importance when attempting to measure

the listed parameters at the levels specified.

5.2 The quality of the data measur ed will depend on

which testing method and calibration techniques are

used. Consequently, trends observed in the values may

be more meaningful than absolute values.

6 Units

6.1 Parts per billion (ppb) is equivalent to ng/mL or

μg/L.

6.2 Parts per million (ppm) is equi valent to mg/L.

6.3 Micron is a unit of length equa l to one millionth of

a meter, or one thousandth of a millimeter.

6.4 Colony Forming Units (CFU) is a measurement of

bacteria organisms.

7 Description of Parameter Tests

NOTE 2: Since SEMI Guidelines do not require analytical

data or methods to support them, the recommendation of

specific analytical methods are only for informational

purposes. Alternative methods may also be applicable.

7.1 Resistivity (megohm-centimete rs or Mohm–cm)

7.1.1 Resistivity (conductivity) is only measured

accurately with on-line instrumentation.18.25 MOhm is

the theoretical upper limit for pure water at 25°C.

7.2 Total Oxidizable Carbon (TOC) (ppb)

7.2.1 Involves oxidation of organic materials and

detection of carbon dioxide produced by the reaction, as

measured in conductivity or infrared photometry.

7.3 Dissolved oxygen (ppb) is onl y measured

accurately with on-line instrumentation.

7.4 Particulate Matter (Particles/L )

7.4.1 On-line methods using laser technology are

recommended for accurate trend analysis.

7.5 Bacteria (CFU/L)

7.5.1 Triplicate samples are cultured based on the

ASTM method F 1094 using a minimum sample size of

1L.

7.6 Silica

7.6.1 Total Silica (ppb) may be mea sured by Graphite

Furnace Atomic Absorption Spectrophotometry

(GFAAS), Inductively-Coupled Plasma Atomic

Emission Spectroscopy (ICP-AES) or Inductively

Coupled Plasma Mass Spectroscopy ( ICP-MS).

7.6.2 Dissolved Silica (ppb as SiO2) may be measured

by heteropoly blue photometry or by Ion

Chromatography.

7.7 Ions and Metals (ppb)

7.7.1 Many anions and cations may be determined

using Ion Chromatography.

7.7.2 Up to 68 metals may be determined by GFAAS,

ICP-AES, or ICP-MS. Most typically measured metals

are shown in Table 1.

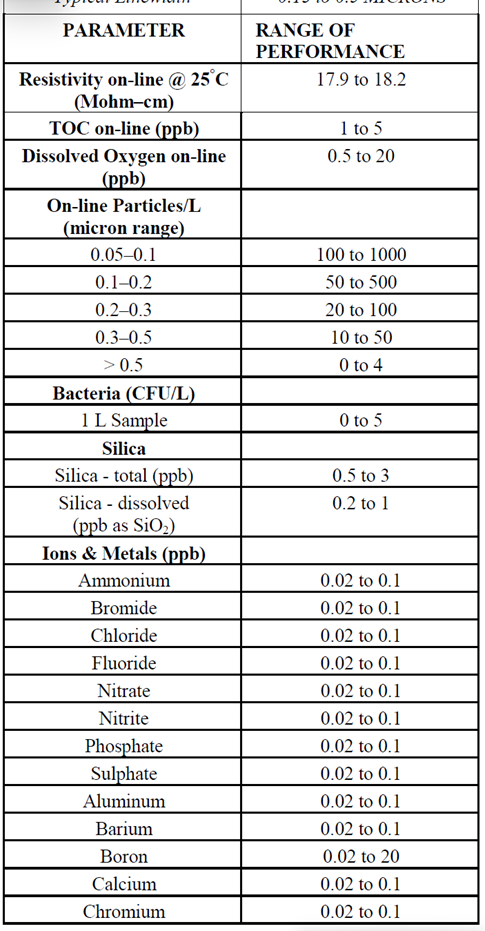

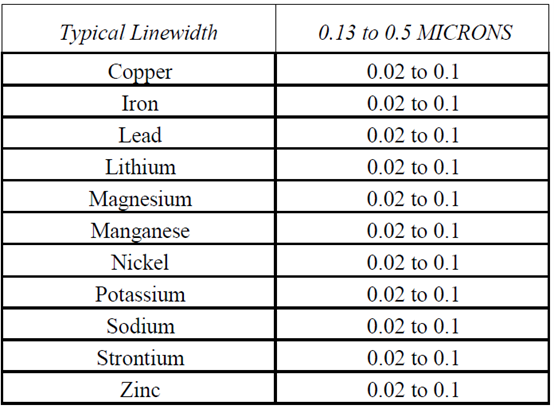

8 Parameters and Typical Concentrations

8.1 Table 1 lists each parameter with its range of

performance.

Table 1 Parameters and Range of Performance

NOTICE: SEMI makes no warranties or

representations as to the suitability of the standards set

forth herein for any particular application. The

determination of the suitability of the standard is solely

the responsibility of the user. Users are cautioned to

refer to manufacturer’s instructions, product labels,

product data sheets, and other relevant literature

respecting any materials mentioned herein. These

standards are subject to change without notice.

The user’s attention is called to the possibility that

compliance with this standard may require use of

copyrighted material or of an invention covered by

patent rights. By publication of this standard, SEMI

takes no position respecting the validity of any patent

rights or copyrights asserted in connection with any

item mentioned in this standard. Users of this standard

are expressly advised that determination of any such

patent rights or copyrights, and the risk of infringement

of such rights, are entirely their own responsibility.